|

|

Aileron drive bolt alignment |

|

|

|

Navigation & Acknowledgements |

6 pictures on this page - scroll down to see the rest

Aileron drive bolt alignment tool: 2003 01 16.

Canon AV-1, Fujichrome Velvia 50.

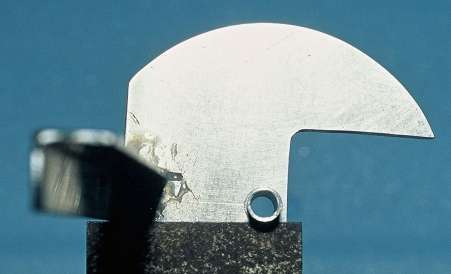

Aileron drive bolt alignment tool, parked on an old vee-block for the picture. It was constructed from various aluminium offcuts.

Aileron drive bolt alignment tool: 2003 01 16.

Canon AV-1, Fujichrome Velvia 50.

Aileron drive bolt alignment tool. This view shows the two relationships which the tool controls. First, from the hinge flange leading edge pushed into the corner of the angle to the bolt shank contained within the tube. Second, from the bolt shank to the leading edge, which should be flush with the curved edge here uppermost.

Aileron drive bolt alignment tool in use: 2003 01 17.

Canon AV-1, Fujichrome Velvia 50.

Use of the aileron drive bolt alignment tool on the root end of the starboard aileron. You can't see it from this angle, but you'll just have to trust me that the aileron LE lines up with the curved side of the jig. This is a dry run, to confirm the position of XA2.

Male plug for aileron root layup: 2003 01 21.

Canon AV-1, Fujichrome Velvia 50.

The time spent in making up this male mould was well repaid. Using it, the second (starboard) aileron root layup was so much easier than the first, done according to the manual.

Tool for aileron hinge pin alignment: 2003 02 01.

Canon AV-1, Fujichrome Velvia 50.

This second alignment tool is used to confirm that the distance between the aileron hinge pin and the drive bolt is the same on each aileron.

Using hinge pin alignment tool: 2003 02 01.

Canon AV-1, Fujichrome Velvia 50.

Having used the first alignment tool to make sure the drive bolt is in a correct relationship with the hinge flange, this second tool might appear redundant. However, I found it worthwhile, as without it the hinges could finish up at slightly different distances from the drive bolts. Leaving the tool in position while the flox pads for the hinge cured gave peace of mind.

|

|

|

go to next picture page |

|

|

||

| Return to Rowland's home page |

| This page last updated 2013-10-16. I try to make this page as accessible as possible, by adhering to HTML 4 standards. |

|

|

| I welcome comments on this website. However, because of the amount of spam it attracts, I no longer post a direct e-mail address on any page. Instead, please click here to contact me. You will have to confirm that you are human before the message will be sent on to me. | ||