|

|

Drilling the torque tube hole in the seat face |

|

|

|

Navigation & Acknowledgements |

5 pictures on this page - scroll down to see the rest

checking CS04 position: 2008-08-14

Nikon Coolpix 8400

The position of the hole for the controls in the seat front face is constrained by the space needed for the large washers on the bolts securing CS04, which have to clear the thigh-support ribs under the seats. I had glassed-in the ribs as far apart as possible, but this still leaves little room for manoeuvre with CS04 considering how far apart are the upper pair of AN970-3 washers.

checking distance apart of torque tube holes: 2008-08-14

Nikon Coolpix 8400

This is a temporary trammel made by clamping a couple of pieces of plywood to a metre stick, being used to check the centre-to-centre distance of the holes in the seat fronts for the aileron torque tubes. Although it is nice to get the tubes exactly parallel, in fact the dimension is not quite so critical here at the forward end; it's more important aft of the seats where the ends of the CS05s have to line up precisely with the brackets on CS10, so that the pitch pushrods are centred within the roll torque tubes. Having marked vertical centre-lines at the required positions on the rear of the seat faces (a compromise between leaving room for the AN970-3 washers on the bolts securing the CS04s and getting the CS04 centres exactly 26.25" apart), I drilled small holes to project the lines through onto the front face of the seats.

marking position of torque-tube hole: 2008-08-14

Nikon Coolpix 8400

Here are the small holes on the seat front face, and a line drawn through them.

drilling torque-tube hole: 2008-08-14

Nikon Coolpix 8400

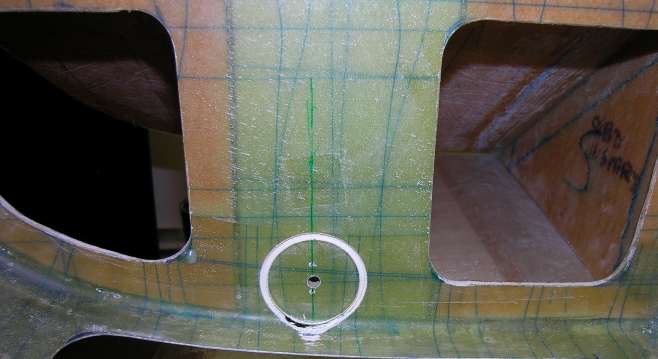

Here I've just started to drill the hole in the seat face for the torque tube. I lined up the pilot of the holesaw on the marked vertical line (well, pretty nearly!) and kept the bottom edge of the holesaw just clear of the cockpit module flange.

torque-tube hole: 2008-08-14

Nikon Coolpix 8400

The completed hole which allows the aileron torque-tube to pass through the front seat face.

|

|

|

go to next picture page |

|

|

||

| Return to Rowland's home page |

| This page last updated 2022-04-05 16:06. I try to make this page as accessible as possible, by adhering to HTML 4 standards. |

|

|

| I welcome comments on this website. However, because of the amount of spam it attracts, I no longer post a direct e-mail address on any page. Instead, please click here to contact me. You will have to confirm that you are human before the message will be sent on to me. | ||