|

|

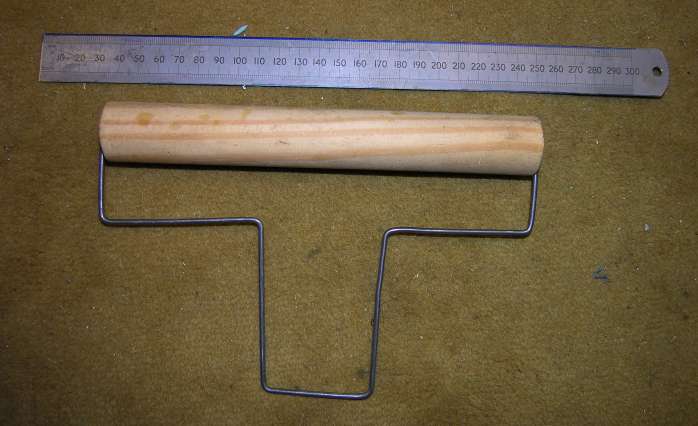

Dowel roller for inside wing repair |

|

|

|

Navigation & Acknowledgements |

3 pictures on this page - scroll down to see the rest

roller for wing repair: 2009-10-27

Nikon Coolpix 8400

Roller to aid making the repair layup on the inside of the wing, made from a piece of 1" dowel and a wire coat-hanger. The wire handle started out much longer and had to be shortened to fit the confined space inside the wing.

BID rolled for wing repair: 2009-10-27

Nikon Coolpix 8400

The BID for the inside layup of the wing repair rolled onto the dowel and retained with a slipknot. The wire handle will get attached to the dowel after both are inserted into the wing cavity through the aileron bellcrank access hole. Note that unlike most BID pieces, this is cut in line with the weave, because it has to align with the weave of the prepreg that it's being laid onto.

wing repair inside layup: 2009-10-27

Nikon Coolpix 8400

Here's the inside layup of the wing repair after the work with the dowel roller, as it appears from the outside. I couldn't get a meaningful picture from the inside. The blue glow through the BID is from the LED lamp I used to help see what I was doing inside the wing.

|

|

|

go to next picture page |

|

|

||

| Return to Rowland's home page |

| This page last updated 2013-10-16. I try to make this page as accessible as possible, by adhering to HTML 4 standards. |

|

|

| I welcome comments on this website. However, because of the amount of spam it attracts, I no longer post a direct e-mail address on any page. Instead, please click here to contact me. You will have to confirm that you are human before the message will be sent on to me. | ||