|

|

right-angle connector cover for wing leveller servo |

|

|

|

Navigation & Acknowledgements |

7 pictures on this page - scroll down to see the rest

milling cover for right-angle connector: 2016-03-23 Panasonic DMC-FT1

Part-way through the making of an insulating cover for the right-angle connector for the wing-leveller servo. Having brought the lump of plastic to a rectangular shape with true faces, here I am chamfering an edge to make it more user-friendly. The workpiece is clamped at 45 degrees in a vee-block, which is in turn held in a machine vice.

milling cover for right-angle connector: 2016-03-23 Panasonic DMC-FT1

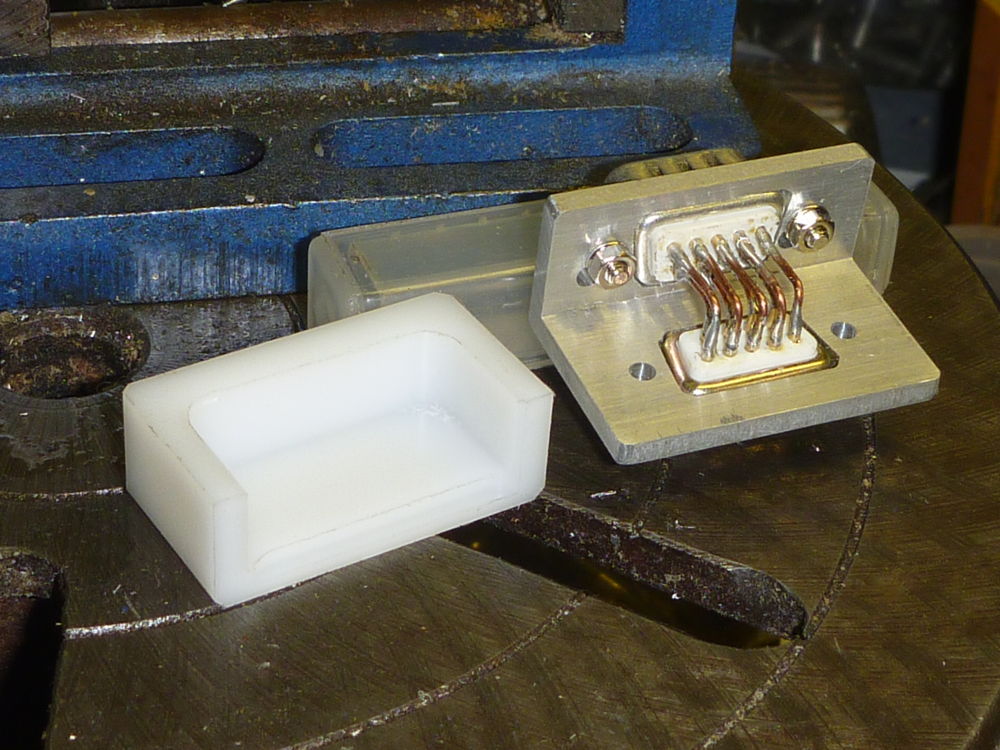

The insulating cover milled to shape, with the right-angle connector for the wing-leveller servo, onto which it will fit.

modified connector jackscrews: 2016-03-23 Panasonic DMC-FT1

A couple of standard jackscrews for D-subminiature connectors modified with the addition of short 4-40 UNC pan-head screws (from my collection of screws recovered from dismantled stuff), which have combination slot and Torx T8 recesses. The extra screws are locked into the jackscrews with Loctite 243. This allows the jackscrews to be turned with a driver smaller in diameter than the screws themselves, and so they will not fall out of the holes made in the cover for the driver.

right-angle connector and cover: 2016-03-23 Panasonic DMC-FT1

The right-angle connector for the wing-leveller servo and the cover for it. The cover has 4 tapped holes for the mounting screws, and 2 larger holes for access to the modified jackscrews that will secure it to the connector on the servo.

right-angle connector with cover: 2016-03-23 Panasonic DMC-FT1

The right-angle connector for the wing-leveller servo with the cover fitted to it. Just visible through the holes in the cover are the heads of the modified jackscrews.

right-angle connector on servo: 2016-03-23 Panasonic DMC-FT1

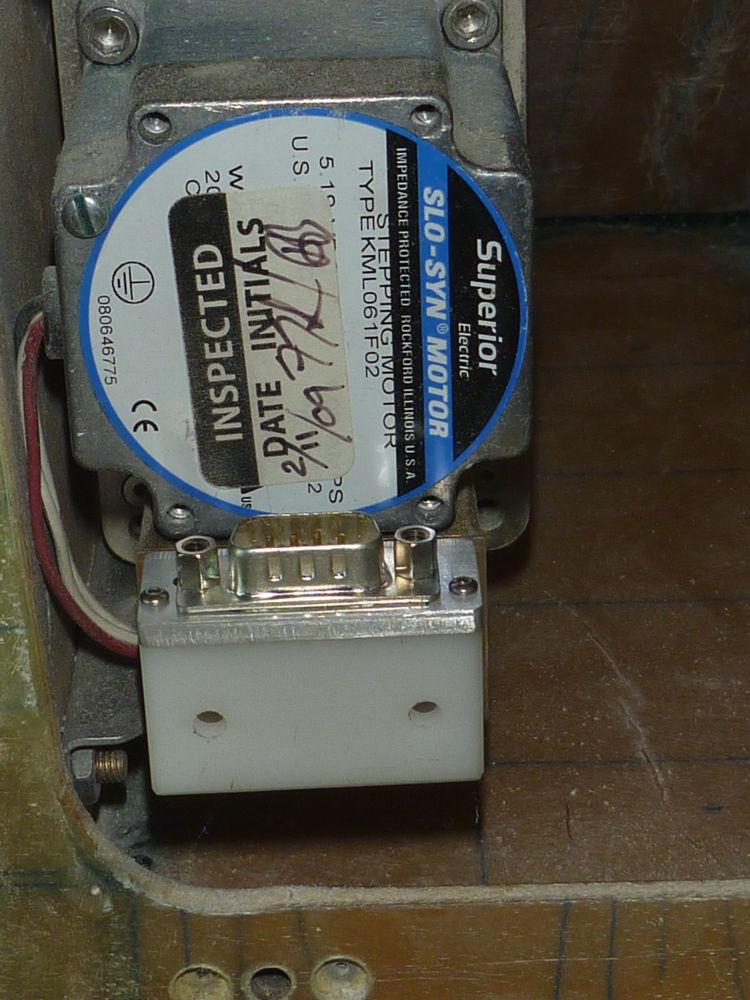

The right-angle connector in place on the servo.

right-angle connector on servo: 2016-03-23 Panasonic DMC-FT1

Looking down the front of the thigh support on the starboard seat towards the right-angle connector in place on the servo. This also illustrates how a normal straight connector and shroud would have protruded considerably beyond the face of the thigh support, and would have been prone to damage from footwear. The right-angle connector allows everything to remain safely behind the flat cover plate.

|

|

|

go to next picture page |

|

|

||

| Return to Rowland's home page |

| This page last updated 2016-05-04. I try to make this page as accessible as possible, by adhering to HTML 4 standards. |

|

|

| I welcome comments on this website. However, because of the amount of spam it attracts, I no longer post a direct e-mail address on any page. Instead, please click here to contact me. You will have to confirm that you are human before the message will be sent on to me. | ||